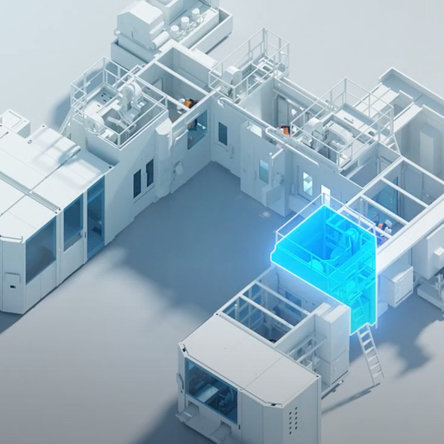

THIS FREELY CONFIGURABLE SYSTEM PLATFORM OFFERS MAXIMUM FLEXIBILITY.

The F series.

The basis is a freely configurable system for shaft and flange components and for end machining, which meets the highest production requirements due to its flexibility and dynamic characteristics. No matter if it’s turning, milling, grinding, or gear cutting – with a selection of numerous applications, you’re always well equipped. This way you can make a CNC lathe into a flexible combination cell specifically adapted for your applications.

EQUIPPED WITH FLEXIBILITY FOR THE FUTURE.

Here is just the right solution for you – fast and standardized with the modular Schuster system. From the simple two-axis standard machine all the way to a complex production line, the F series provides the maximum in flexibility and functionality. At the heart of the machine is the extremely sturdy machine base made of 100% polymer concrete. The individual components are mounted on this base. And if you want to expand later, you can convert the machine from a single spindle to a multi-spindle at any time. Because the system has a symmetrical structure, the direction in which the process runs can also be freely determined – to meet the requirements of your production sequence. In addition, it’s possible to expand using a plug and play design that makes the adaptation to your quantities simple while saving costs.

Schuster is known for its efficient, integrated automation solutions The standard, integrated gripper with an extra-large stroke enables load-bearing capacities of up to 30 kg and achieves optimum processing times. Components can be supplied and removed very quickly with a gripper – in approx. 10 seconds. And with the quick-change system, the jaws can be replaced in just 30 seconds per gripper. That saves time and money.

Direct workpiece transfer together with quick loading and unloading procedures and short setup and conversion times result in high productivity. But not only that – Schuster also offers a truly exceptional feature: The motor spindle is firmly screwed together with the machine base, which damps vibrations and has high thermal stability because it consists of polymer concrete. This ensures a high degree of rigidity and process reliability for professional CNC production. Furthermore, the standard components used are of top quality and provide the highest degree of quality assurance.

Turning, milling, and grinding as well as gear cutting for shafts and flange components with consistent, high quality. The unique motor spindle concept ensures a high degree of rigidity in that the spindle is affixed to the sturdy machine base made of polymer concrete. The F series also achieves professional results quickly in HRC machining and grinding. Can be expanded to include the powerful Direct Drive tool turret drive with 12 tool slots.

Efficient four-axis processing and synchronous processing reduce processing times to a minimum, achieving groundbreaking cycle times for vertical lathe processing.

THE ADVANTAGES OF THE F SERIES:

WE HAVE ALWAYS MADE IT POSSIBLE. IN THE BEST

GERMAN MAKER TRADITION.

With over 40 years of experience, we bring performance and demand forward and to you all over the world. We do this in Germany with the usual high Schuster quality from Bavaria. And only stop when today's standards fit perfectly. This also includes our close-meshed service network for maximum machine availability and to extend the economic service life. Your personal, qualified contact person supports you via remote service or directly at your site for fault diagnosis and rectification.

NXT SERIES

The gateway to the future of automatic vertical machining.

V SERIES

This smart solution for twin and double-sided machining is highly productive.

Join our team

We look forward to new colleagues in general and to your application in particular.