YOUR GATEWAY TO THE

FUTURE OF MACHINING.

THE NXT SERIES.

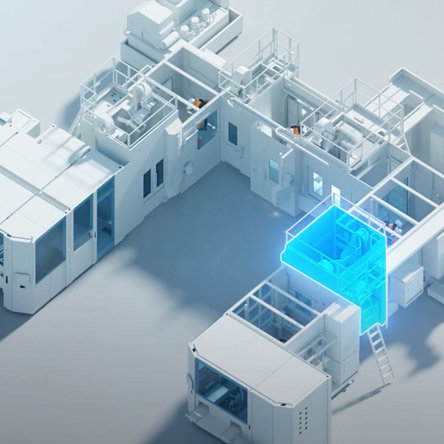

With nxt, Schuster gives you access to a whole new territory. Specifically, the world of automatic vertical machining for customized series production in which you benefit from all of the advantages of a pick-up lathe: from the compact, space-saving structure and user-friendly design to optional, customized features and savings in both energy and costs, thanks to especially high production capacity in a small space.

THE FIRST PLUG AND PLAY MACHINE THAT FEELS SPECIALLY TAILORED TO YOUR NEEDS.

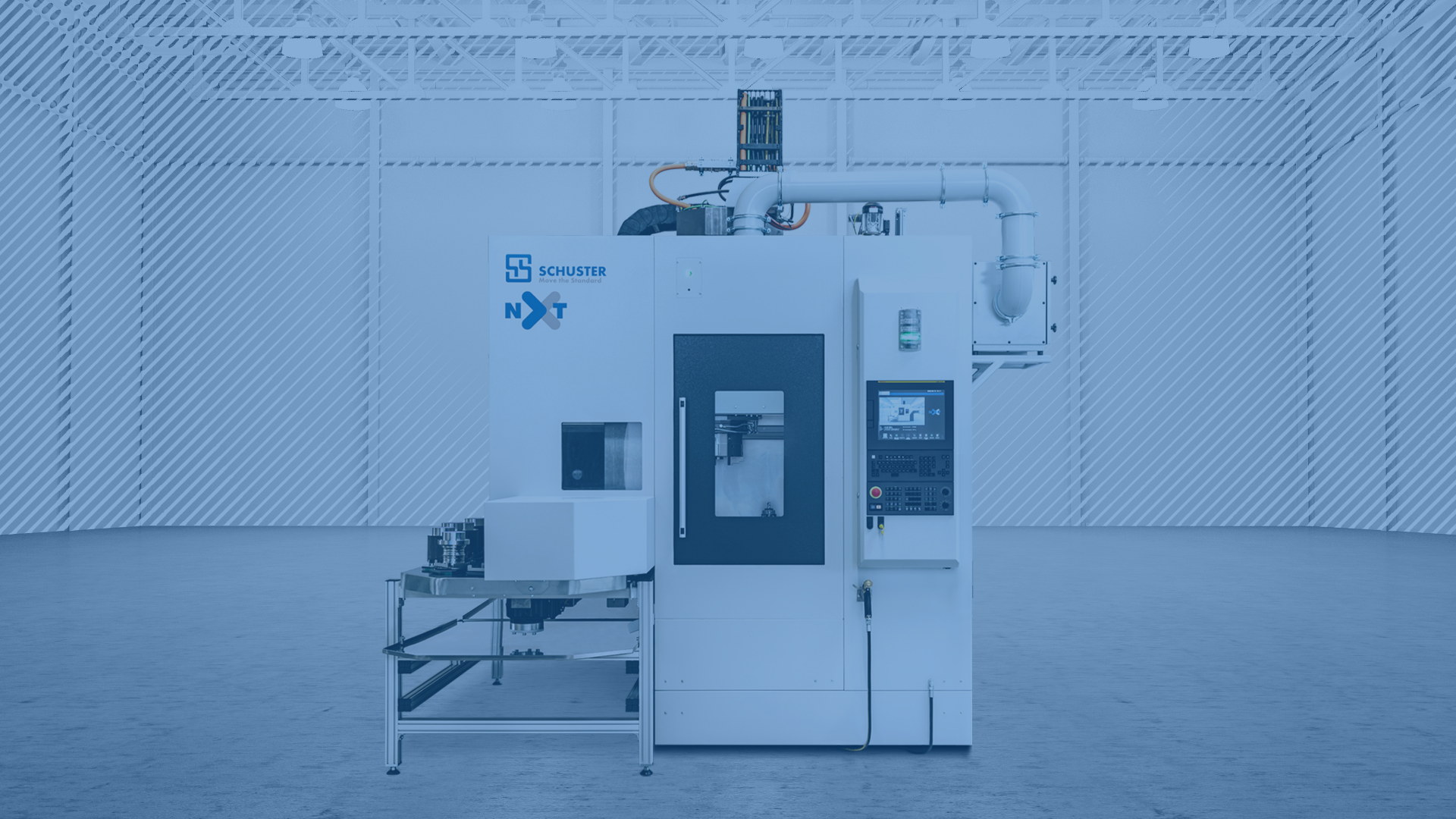

Even the most basic version of the Schuster nxt has exceptional features. For example, the machine base made of 100% polymer concrete, the guide systems (45 mm guideways in the X and Z directions) and the high-precision spindle with extra-large spindle bearings (120 mm) and an A6 spindle nose. The highlight: The machine is available as either a left-hand or right-hand version, depending on your site situation. Both FANUC and SIEMENS can be used.

Milling slots and machining cross-bores or key flats on the circumference or on the face are among the many machining operations that can be performed professionally, economically, and quickly with our driven tool turret. The ability to choose between VDI40 and BMT55 with the tool turret is a good argument for complete machining.

For the greatest precision when drilling holes positioned either within or outside the center of rotation, the Schuster nxt is also available with a HSK63 drilling, milling, or reaming spindle. When combined with Schuster’s patented spindle clamping system, this machine version can perform precision series drilling that would otherwise not be possible. The spindle clamping technology for disconnecting the c-axis (main spindle) operates hydraulically with clamping forces of up to 300 Nm. Its positioning, directly above the spindle nose, suppresses even micro-vibrations perfectly and ensures that precision tolerance requirements down to 15 µm are met.

Holes with diameters of up to 65 mm (depending on the workpiece material) can be drilled with no trouble at all with our “high-performance” drilling package. A generously sized coolant-lubricant pump with a capacity of 60 l/min. removes the higher volume of chips that result from machining. With its standardized VDI tool interface, the drilling console, milled out of the complete body and affixed directly to the machine base, is used to meet other requirements, such as force impact or quick tool setup.

THE ADVANTAGES OF THE NXT SERIES:

WE HAVE ALWAYS MADE IT POSSIBLE. IN THE BEST

GERMAN MAKER TRADITION.

With over 40 years of experience, we bring performance and demand forward and to you all over the world. We do this in Germany with the usual high Schuster quality from Bavaria. And only stop when today's standards fit perfectly. This also includes our close-meshed service network for maximum machine availability and to extend the economic service life. Your personal, qualified contact person supports you via remote service or directly at your site for fault diagnosis and rectification.

F SERIES

This freely configurable system platform offers maximum flexibility.

V SERIES

This smart solution for twin and double-sided machining is highly productive.

Join our team

We look forward to new colleagues in general and to your application in particular.