Standstill is not an option: The path to the Master’s degree.

Warum wir bei Schuster auf kontinuierliche Weiterbildung und die Prämierung von Meisterstücken setzten.

For Schuster, one thing is clear: In today's fast-paced world, which is characterized by constant change, lifelong learning and professional development are the key to success. In our day-to-day work, this means recognizing individual potential, supporting developments and offering long-term prospects. An important component of personnel development is master craftsman training. It enables our employees to continue learning in their specialist area and strengthen their leadership skills.

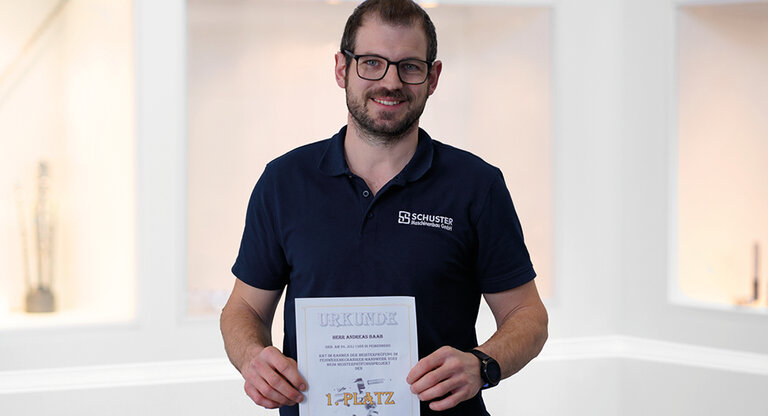

Andreas Baab successfully passed his master craftsman's exam in December 2022 and earned the title "Master of Precision Mechanics". He looks back positively on his training time: "I can only encourage everyone to follow this path. Those were very intense, very fun times. After the theory exam, the other master students and I would ask each other, "What are we going to do next?" The plan to become a master was already clear to Andreas when he started his professional life. But it wasn't put into practice until a few years later: "With a family and a house, I had to set priorities accordingly. Without the great support of my wife and the support of Schuster, it certainly wouldn't have worked out with the master's title."

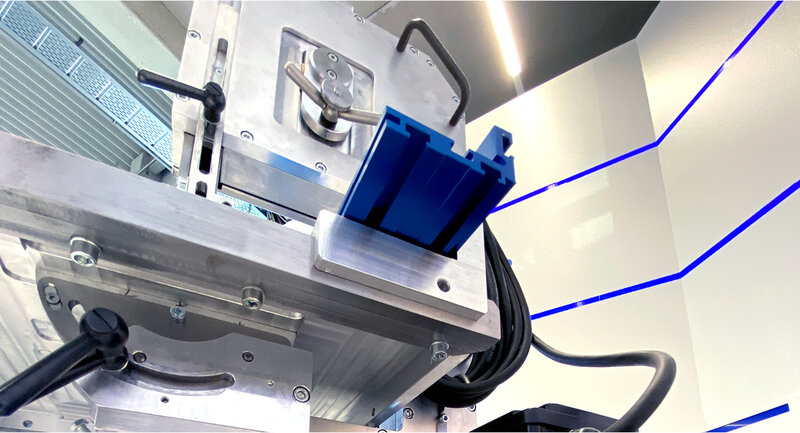

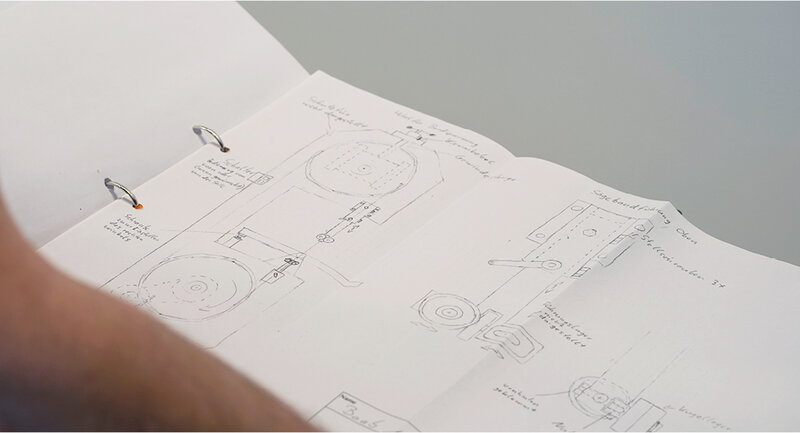

The master craftsman training consists of several modules that impart both theoretical knowledge and practical skills. The highlight of the training is the production of the masterpiece: This is a practical project in which the prospective master craftsmen have to demonstrate the knowledge and skills they have learned. Andreas Baab had to make a band saw in his exam. "Nobody really expected that," he recalls. Within two hours, the first sketch had to be completed, which was decisive for the next steps. After that, Baab devoted himself to the complete elaboration of the saw: from the CAD drawing to the calculation to the machining and assembly.

With great success: His outstanding performance was rewarded with an award for the best masterpiece. The selection of masterpieces is evaluated by a jury of internal and external experts who judge the creativity, quality and implementation of the project. "Of course, I was very happy about the award. I am proud that everything could be implemented as well as planned and that the saw works so well," says Andreas Baab. Looking back, what would he do differently? "Nothing." What advice would he give to future master students? "Get a few years of work experience before you do the master's - there's no substitute for practical experience."

Baab used the master’s training to jump-start his career. With the title of master craftsman, new doors opened for him at Schuster: "Schuster has created my position as head of pre-assembly and instructor especially for me. And the path continues: with Andreas Baab, we have gained another master craftsman in the Schuster team and are pleased to be able to fill an important position in the management team with him.