ESSENTIALLY, IT’S ALL ABOUT YOUR WORKPIECE. BUT WE FOCUS ON EVEN MORE.

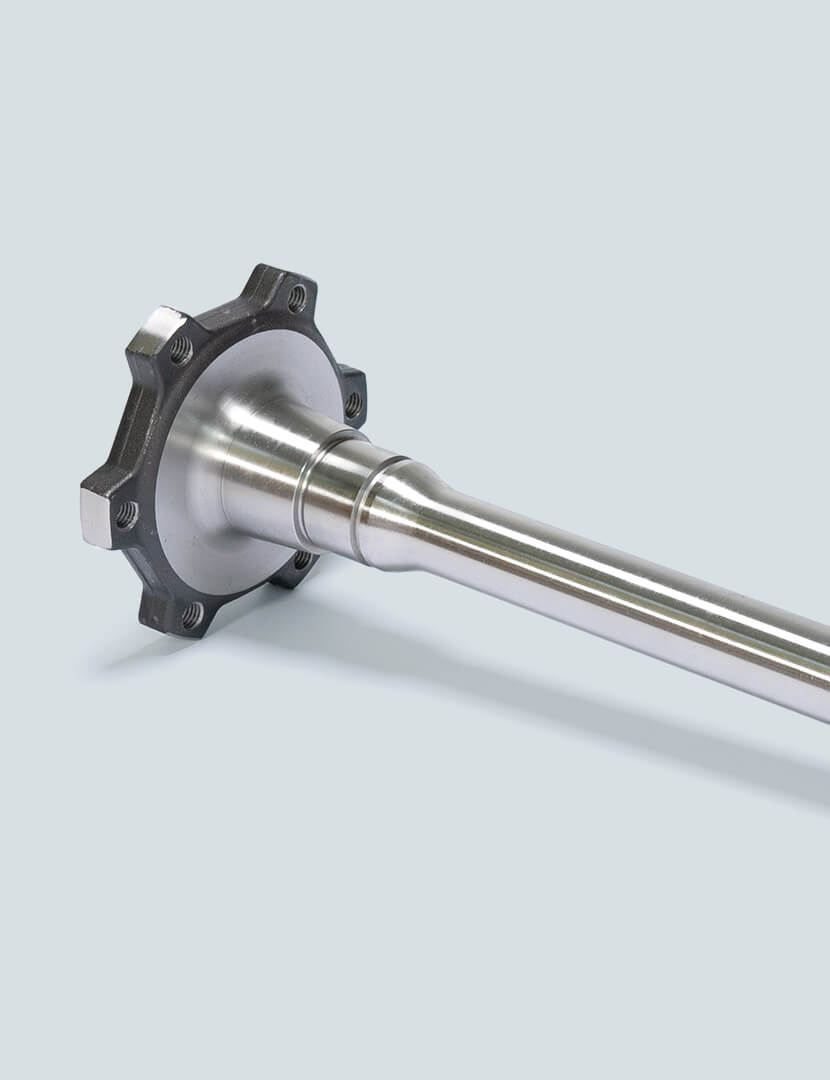

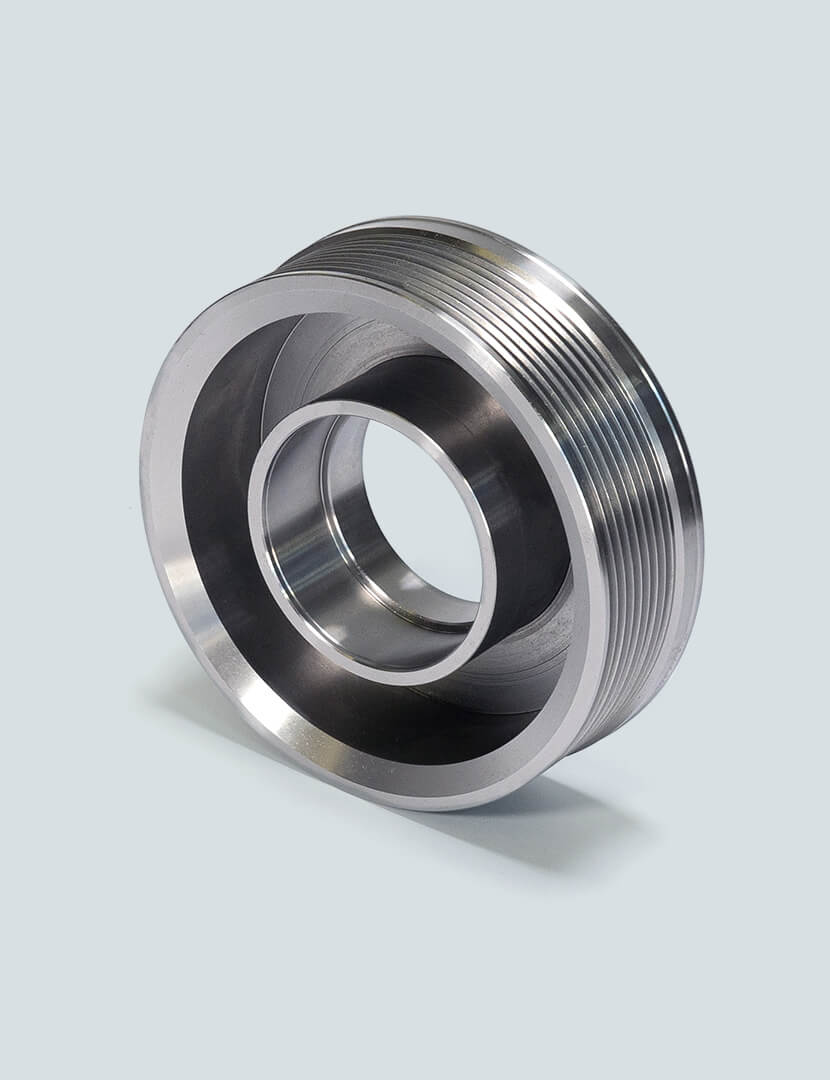

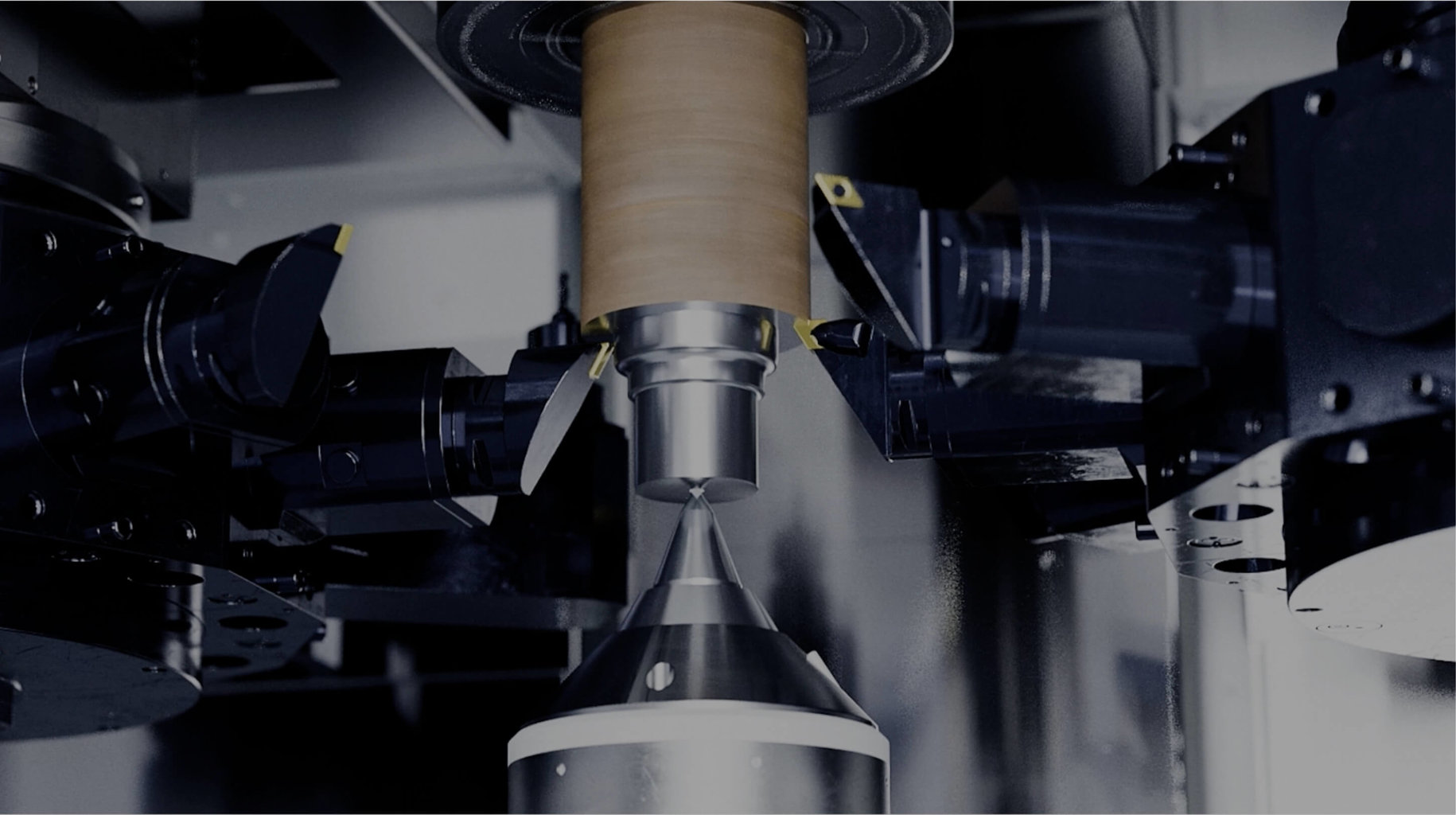

With over 40 years of experience we offer specialized expertise, above all in the processing of shaft-shaped and disc-shaped parts. We provide you with the actual machining process (turning, milling, grinding, and gear cutting), depending on the requirements of your workpiece. But because our work always begins before the workpiece and because we always think beyond it, we often implement individualized solutions that include the entire process – for example, for the automated supply of parts, for subsequent quality control, or for other steps that follow.

WAS IST IHR STANDARD?

Join our team

We look forward to new colleagues in general and to your application in particular.