THE FUTURE IS

TWICE AS SMART.

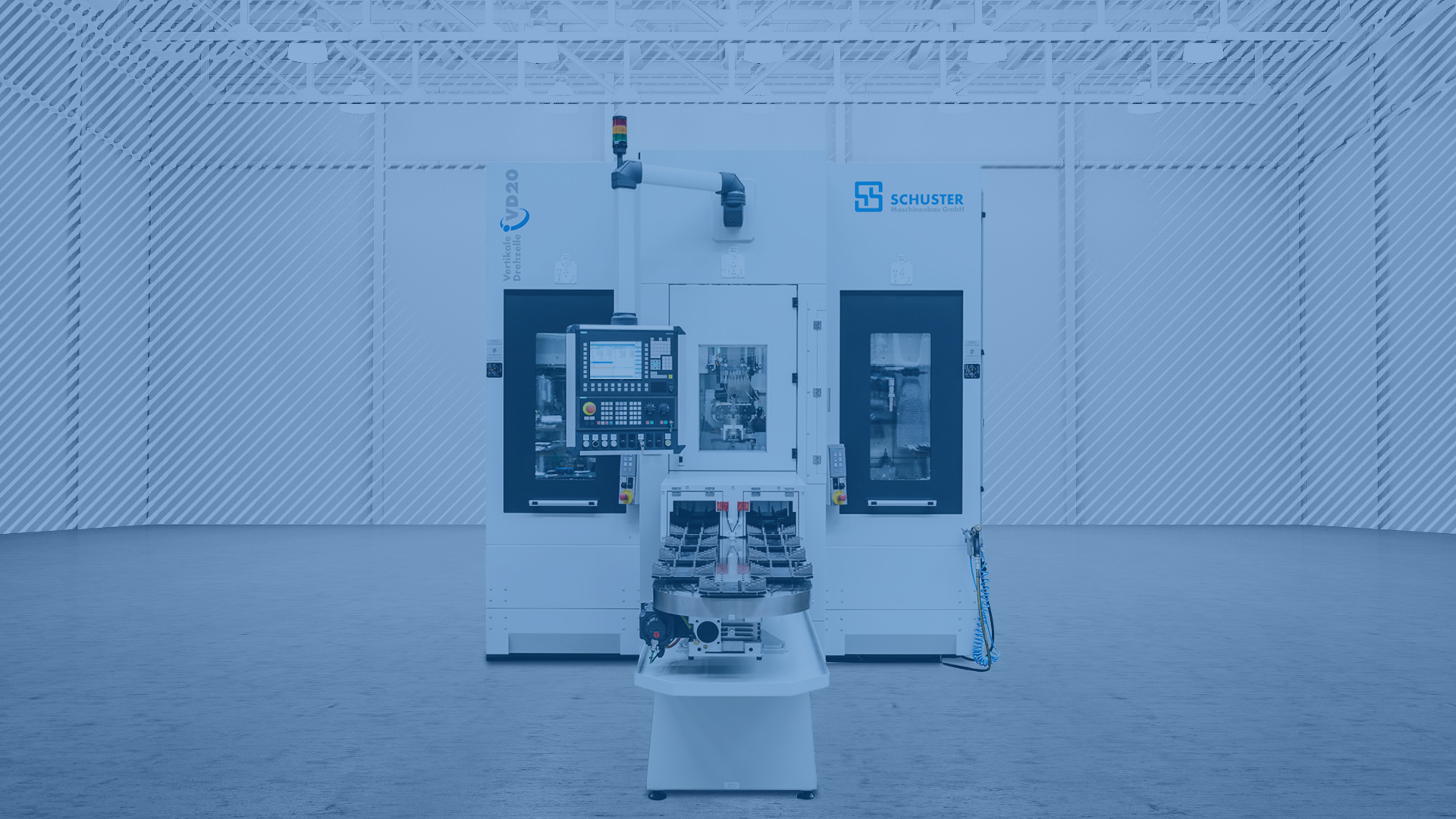

The V series.

The vertical structure of the V series makes the best use of your resources in terms of production area. Fast, compact, and productive, the V series, with its vertical double spindle units, is outstanding for operations such as twin processing or double-sided machining, ensuring the best results. The loading and unloading times are lower than those for conventional pick-up solutions due to the standardized handling system between the two work areas. As before, additional operations such as deburring, turning workpieces, measuring, inspecting, cleaning, and marking can be carried out by the handling system during auxiliary process times.

THE SMART, PRODUCTIVE SOLUTION FOR TWIN AND DOUBLE-SIDED MACHINING:

The double spindle machines have two separate rotation modules, so that two rotationally symmetrical components with diameters of up to 250 mm can be machined simultaneously. The same high efficiency – for both simultaneous and classic double sided processing. The two modules are completely insulated for the greatest precision and stability – making the conduction of vibrations and temperature changes impossible. Moreover, the bases of the machines have high thermal stability because they are made of 100% polymer concrete. As an option, patented spindle clamping technology provides the rigidity required for milling and drilling, which significantly increases the processing quality.

Because the modules are identical in construction, they ensure high workpiece quality and cutting performance during both soft and hard machining. They operate with powerful, high-torque main spindles in addition to tool turrets with 12 tool slots. Optional version with Direct Drive.

The key advantage of the V series: Additional tasks such as deburring, measuring, brushing, or inscribing can be carried out efficiently during non-productive periods. No matter if it’s an NC handling gripper or robot-based automation – both provide you with the maximum scope for action. This is what we call the production of tomorrow. Part transport can also be carried out quickly in very small spaces due to processing capability. To ensure speed and efficiency, the same conveyor belt is also used to supply and to remove the parts.

Like all Schuster machines, the V series also features a very compact design. That saves costs and space. The two modules, which are 850 mm wide, require an installation area of just 20 to 24 m2. The switching cabinet, chip conveyor, and coolant-lubricant unit can be positioned as desired.

WE HAVE ALWAYS MADE IT POSSIBLE. IN THE BEST

GERMAN MAKER TRADITION.

With over 40 years of experience, we bring performance and demand forward and to you all over the world. We do this in Germany with the usual high Schuster quality from Bavaria. And only stop when today's standards fit perfectly. This also includes our close-meshed service network for maximum machine availability and to extend the economic service life. Your personal, qualified contact person supports you via remote service or directly at your site for fault diagnosis and rectification.

NXT SERIES

The gateway to the future of automatic vertical machining.

F SERIES

This freely configurable system platform offers maximum flexibility.

Join our team

We look forward to new colleagues in general and to your application in particular.