Sorry, ChatGPT – Graph AI sets the standard for us.

The digital transformation has fundamentally changed our working world: Automated processes and artificial intelligences such as ChatGPT have already arrived in the modern working day - but have also shown their limitations in the past. For example, the well-known AI assistant lacks the understanding of context and background knowledge to generate texts with depth of content. Recognizing and making logical connections between different concepts and facts also poses major challenges for the chatbot. At Schuster, we are aware that the future of the manufacturing industry depends on advanced technologies. However, to meet modern requirements, more comprehensive solutions than ChatGPT & Co. are needed.

Modern challenges of the manufacturing industry.

In a competitive industry like manufacturing, companies need to be able to produce new products quickly and individually at low cost. The integration of software into production planning and control has made flexible automation possible - but it has also brought new challenges. One of these is disruptions that can occur during the production process. They often lead to longer downtimes and are difficult to rectify due to the complexity of the systems involved. This is where intelligent solutions are needed that effectively support skilled workers through insights gained from data and experiential knowledge.

Error management on a new level

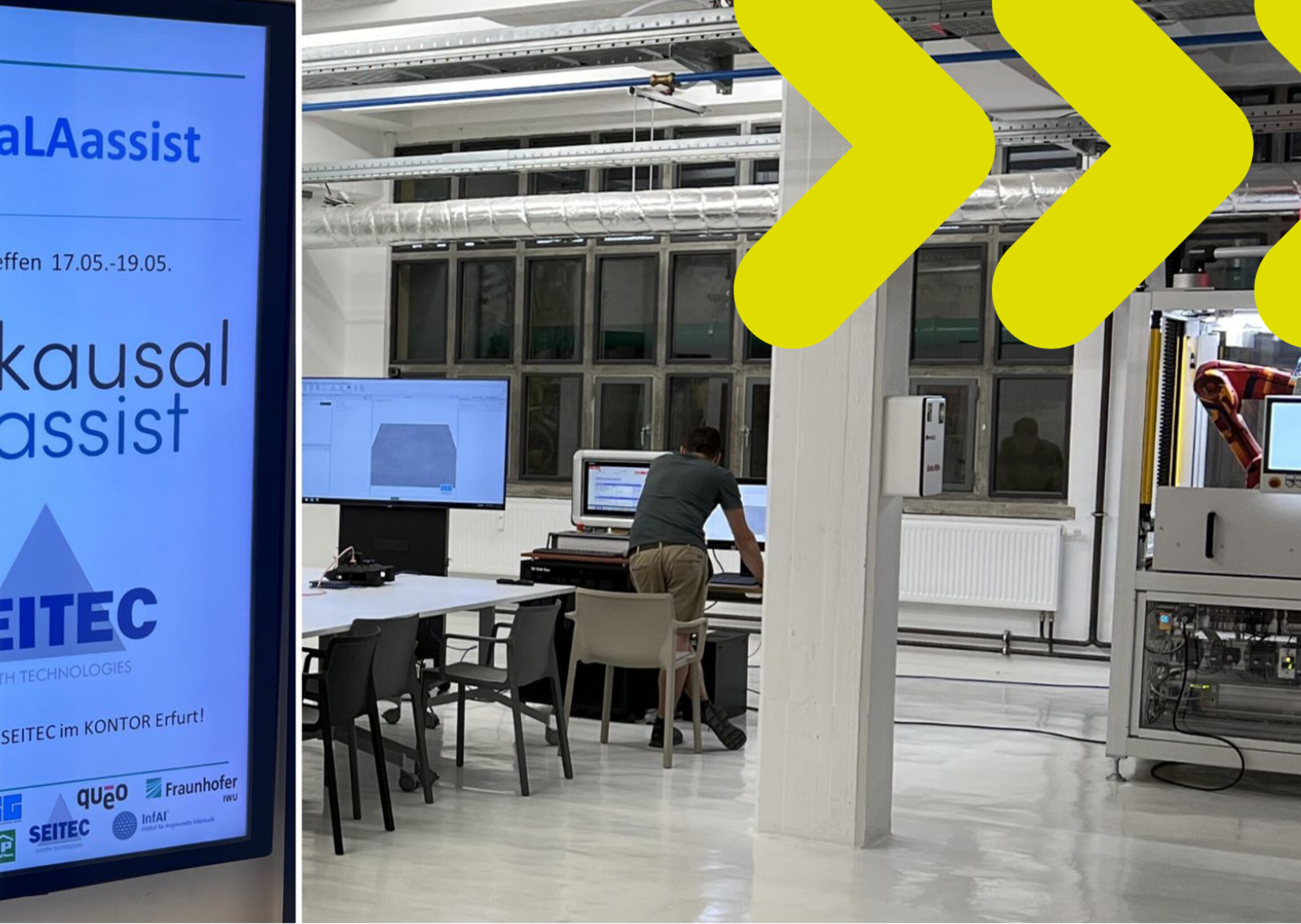

This is exactly where our partnership with the renowned research institutes Fraunhofer IWU, the Institute for Applied Computer Science, and several industry partners, who play a leading role in research in the field of Industry 4.0, comes in. Our joint research project "KausaLAssist" aims to develop a directed graph that combines domain-specific knowledge with AI insights about causal relationships. This graph represents the learned knowledge in a readable way for both humans and machines and enables a transparent derivation of effective troubleshooting measures. Not only can faults be identified, but their causes can also be precisely determined. This enables specialists to make informed troubleshooting decisions and initiate effective measures. At the same time, the graph-based approach provides a deep understanding of the interrelationships between the various components and helps to optimize production processes in a targeted manner.

In addition to the ability to continuously learn and adapt, the explainability of the system is another advantage. In contrast to pure machine learning models like ChatGPT, learned insights and recommendations of the Graph can be presented transparently. The result: better traceability of results and informed decision making.

We are convinced that the use of Graph AI has the potential to revolutionize the production process in the manufacturing industry. Not only can disruptions be detected and resolved more quickly, but preventative measures can be taken to avoid future problems. This leads to increased productivity, reduced downtime, and ultimately improved competitiveness. Let's move the standard!