Fully unmanned shift – thanks to VD20 with shuttle box

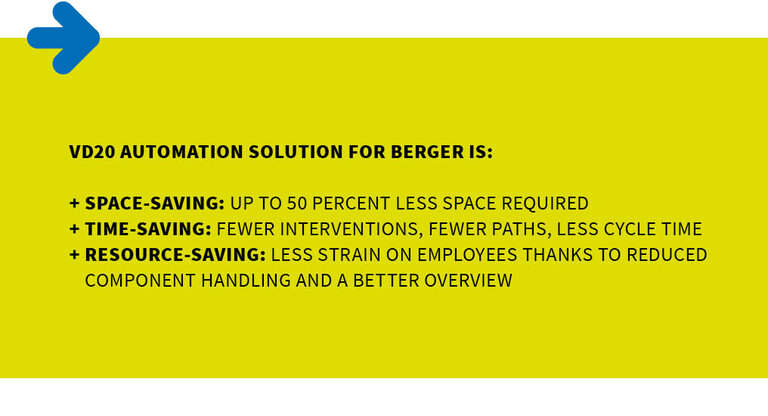

More machine autonomy. More resource savings. More employee relief. This was what the Berger Group was looking for in its search for the ideal automation solution in the smallest of spaces. They found what they were looking for at Schuster Maschinenbau - the VD20 with robot and integrated shuttle box.

At the Berger plant in Wertach, things are now much simpler and faster in the production of components for the automotive sector. This is because the VD20 from Schuster takes over the job for an entire shift of employees. This means that the operators can now concentrate on more important things instead of manual handling. All they have to do is dock the component container onto the machine once and the robot will then process the drawers autonomously.

The space requirement was also halved thanks to the compact and vertical alignment of the VD20. As a result, it was possible to rearrange the sequence so that everything now runs neatly in a row - which also has the advantage of shorter distances and a better overview. And best of all: simplified handling and shorter distances have noticeably reduced the cycle time for processing.

The successful implementation was certainly also due to the goal-oriented cooperation at eye level and the shared values of both companies. In addition to the requirement analysis at the beginning, the helpful feedback from the Berger workers during the test run provided many positive impulses for optimizing the processes. Berger was particularly impressed by the flexible use of synergy effects - such as the desired use of Berger's own ball screws and the integration of the shuttle box. The result: 100 percent customer satisfaction!